water vapor permeability test procedure vendor|water vapour permeability test method : wholesaling MOCON provides Water Vapor Permeation Analyzers for testing water vapor & moisture transmission rate of films and packages for many applications. Call us today! Cifra: Simplificada (violão e guitarra) Favoritar Cifra. Tom: Bb (forma dos acordes no tom de G) Capotraste na 3ª casa. [Intro] C G/B C D4 Em7 D4 C G/B C . Grande é o Senhor. .

{plog:ftitle_list}

WEBSex Porn XNXX Porn,Bokep Indo XNXX indo,a-xnxx.COM,XXX russia,Xxx thailand,xxx indo,xnxx russia,sex xxx,xnxx thailand,malay sex,xxx malay,Anal Sex Tube Movies at xHamster Com Porn PORNHUB COM.XNXX,XVIDEOS.COM,Free XXX VIDEO,Bokep Indo, Top; A - Z? This menu's updates are based on your activity. The data is only saved .

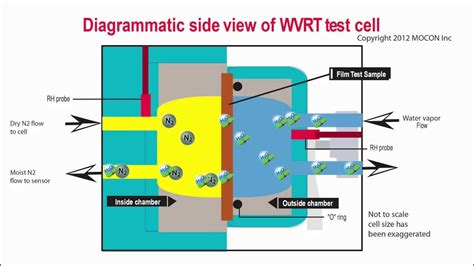

MOCON provides Water Vapor Permeation Analyzers for testing water vapor & moisture transmission rate of films and packages for many applications. Call us today!Labthink has the most complete product line of water vapor permeability testers in packaging industry worldwide. Water vapor permeability is a measure of the passage of water vapor through a membrane.

Labthink has the most complete product line of water vapor permeability testing instruments in packaging industry worldwide. Water vapor permeability is a measure of the passage of water vapor through a membrane. Detailed video explanation of ASTM E96-22 standard desiccant and water test methods for water vapor transmission rate of materials. The ASTM E 96 test method covers the determination of the water vapour transmission of materials through which the passage of water vapour may be significant such as paper, plastic films, other sheet materials, fibreboard, . Two standard test methods are most common: ASTM F1249 (“F1249”) Standard Test Method for Water Vapor Transmission Rate Through Plastic Film and Sheeting Using a Modulated Infrared Sensor and ASTM E96 .

This test measures water vapor transfer via semi-permeable and porous samples. The ASTM E96 test measures the rate at which water vapor passes through a material over time, and .

Oxygen transmission rate (OTR) and water vapor transmission rate (WVTR) are two key material specification properties which determine the shelf life of food packaging. Smithers offers a full .

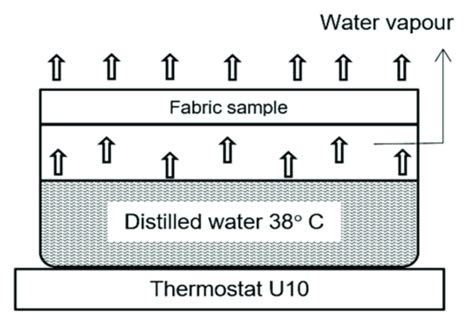

ASTM E96 outlines standardized test methods to determine the water vapor transmission rate of materials. This property, crucial in construction and packaging industries, quantifies the .Cup method is the method used to test water vapor permeability independently based on a simple and perspicuous principle. In cup method, there is certain pressure difference .The modified procedure for water vapor permeability (WVP) is a modification to the established ASTM E96 method for measuring the WVP of films. The E96 method works by putting water in cups and measuring the mass transfer rate of water vapor through films that are.

Definition of WVP – Water Vapor Permeability. The vapor quality passing through the unit area sample vertically in the prescribed time at the speed of g/m²Water vapor permeability is one of the main performance indexes of package materials. As people are attaching more importance to the damp proofing and waterproofing of products, package materials with smaller water vapor permeability becomes the f.3us of package material development and application and is receiving more and more concentrations in recent years.

Cup experiments are the most widely used method to measure the water vapor permeability of porous building materials. For this test, cup assembly is designed to create a vapor pressure gradient across a sample and, thus, to allow vapor diffusion through it. Water vapor permeability is assessed by weighing cup assembly over time.

Oxygen permeability testing is made in accordance with ASTM D-3985, ASTM F-1927 and ASTM F-1307, DIN 53380-3 or JIS K 7126. Water vapor permeability rates can be determined according to ASTM F1249, BS 7406 method A, ISO 9932 or TAPPI T557.“water vapor permeability—the time rate of water vapor transmission through unit area of flat material of unit thickness induced by unit vapor pressure difference between two specific surfaces, under specified temperature and humidity conditions. 3.1.1 Discussion—Permeability is a property of a material,

permeability of a body that performs like a material may be used. Permeability is the arithmetic product of permeance and thickness. water vapor permeance Ñthe time rate of water vapor transmission through unit area of ßat material or construction induced by unit vapor pressure difference between two speciÞcDiscover the importance of water vapor permeation testing. Ensure the barrier properties of packaging materials. Learn why water vapor permeation testing matters.

B# Water Upright 73.4℉ (23 ℃) 50% BW# Water Inverted 73.4℉ (23 ℃) 50% C Solid Desiccant Upright 90 ℉ (32.2 ℃) 50% D Water Upright 90 ℉ (32.2 ℃) 50% E Solid Desiccant Upright 100℉ (37.8 ℃) 90% (#)More common procedures adopted in the market WATER VAPOR PERMEABILITY (WVP), BS 7209 PROCEDURE METHOD CUP ORIENTATION . The study of permeation and diffusion of gases through polymeric matrices has been of great scientific interest for various applications such as packaging and development of membranes for separation [1, 2].Products such as food, medicines, electronics, photovoltaics, etc, are prone to degradation in the presence of water vapor [3, 4].Therefore, study of oxygen and .

water vapour permeability test method

ASTM E96 Full Name. ASTM E96 – Standard Test Methods for Water Vapor Transmission of Materials. Scope. ASTM E96 outlines standardized test methods to determine the water vapor transmission rate of materials. This property, crucial in construction and packaging industries, quantifies the amount of moisture that permeates a material over a specific area and time. Load the test sample onto the test cup. The water vapor permeability tester places the positive cup in the test apparatus. After equilibrating, weigh the object to obtain its initial weight. Then, testers test and weigh it again. The formula uses the mass difference from the second weighing. It uses the difference to find the sample’s .All data for the water vapor permeability testing machine meet the standard parameters, for example, ISO 8096, BS 3424-34, and BS 7209. . Welcome to TESTEX – a professional textile testing instrument supplier – Water Vapour Permeability Tester TF165A is on . You will get a more detailed water vapour permeability test procedure if you . Standard Test Methods for Water Vapor Transmission of Materials E0096-00E01 ASTM . permeance, and permeability are stated in Table 1. All conversions of mm Hg to Pa are made at a temperature of 0°C. 1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user .

What does the ASTM E 96 Method describe? The ASTM E 96 test method covers the determination of the water vapour transmission of materials through which the passage of water vapour may be significant such as paper, .Developed by TQC Sheen, our paint testing specialist brand, our permeability cups are used to determine the water-vapor transmission of paints, varnishes, coatings, coating systems and related products.. You’ll find our permeability . water vapor transmission rate Ñthe steady water vapor ßow in unit time through unit area of a body, normal to speciÞc parallel surfaces, under speciÞc conditions of temperature and humidity at each surface.Ó 4. Summary of Test Methods 4.1 In the Desiccant Method the test specimen is sealed toFIELD MANUAL 110 Table 17-1.—A glossary of abbreviations and definitions used in permeability calculations K = Coefficient of permeability in feet (meters) per year under a unit gradient. Q = Steady flow into the well in ft3/sec [m3/sec]. H = The effective head of water in the well in feet (m). For packer tests, determining the effective head is defined

Standard test methods for water vapor transmission of materials. E96-95. In Annual Book of ASTM Standards American Society for Testing and Materials, Philadelphia. Google Scholar. Bader and Göritz, 1994. . modified procedure for water vapor permeability and explanation of thickness effects. Journal of Food Science, 58 (4) (1993), pp. 899-903. Then, numerically, using the SYRTHES tool for coupled heat and mass transfer. Finally, we will propose a new test procedure to measure the water vapor diffusion coefficient, considering the total gas pressure. In this paper, we are interested in analyzing the cup test method at a macroscopic scale, for water vapor transport in dry materials.gas experiments, as a function of the water vapor permeability. The permeance values are extrapolated to a water vapor activity of 0, since the water vapor permeability strongly depends on the water vapor activity. 2.0 2.5 3.0 3.5 4.0 4.5 5.0 1E-6 1E-5 1E-4 C 3 H 8 C 2 H 6 CH 4 CO 2 O 2 N 2 Diffusivity [cm 2 /s] kinetic diameter [Å] H 2 O H 2

Dry and wet method laser particle size Analyzer agency

After the test a μ-value can be evaluated according to equation (1) (derived from Fick’s law). a p g d GP ˜' ˜ (1) where: μ - water vapour resistance factor (-) įa - water vapour permeability of still air (kgÂASTM D 1653 is a standard test method used to determine the permeability of organic coatings to water vapor and gases. The test involves immersing coated test panels in water or other liquids, and measuring the rate of water vapor or gas transmission through the coating. A correlation between water vapor permeability and density is established. The analysis of liquid uptake by X-ray radiography shows that preferential uptake occurs in the latewood layer.

Key Words: water vapor permeability, water vapor transmission rate, cup method, sensor method, desiccant method and water method 1.Overview: . method measure in accordance with test procedures and calculation formula of ASTM E96 should be identical in ideal situation, water method has not been adopted by domestic standards and even current . There remains a need for developing test procedures that support conservation aims and enable comparative performance testing of coating materials.26 The present work introduces a test procedure that supports conservation goals and . Kamper, SL, Fennema, O, “Water Vapor Permeability of Edible Bilayer Films.” J. Food Sci., 49 (6 .This provides a basis to water vapor permeability testing under special conditions. 2.2 Reference Standard: ASTM E 96 . ASTM E96 is the gravimetric standard with the longest history. It is also the longest-standing standard method for water vapor permeability testing. The first edition was issued in 1953 and has been revised for many times .

Double Column Tensile Tester agency

Learn more about the Michigan Lottery. Read our mission sta.

water vapor permeability test procedure vendor|water vapour permeability test method